You don’t realise how bad modern design has become until something breaks.

A phone screen cracks.

A washing machine stops draining.

A laptop battery dies.

A car sensor throws a fault.

You think: no problem — I’ll just replace the part.

And then you discover:

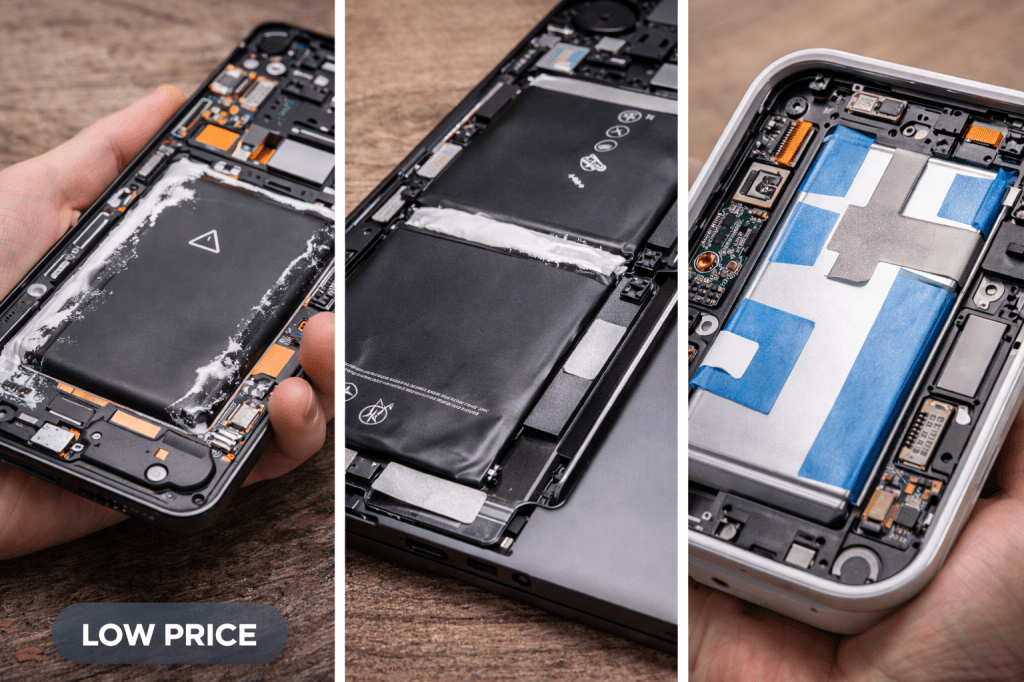

• the battery is glued in

• the panel is sealed

• the screws are proprietary

• the part is coded to the device

• the repair requires special software

• the manual doesn’t exist

At some point, “modern design” quietly became hostile to repair.

Not accidentally.

Not as a side effect.

On purpose.

Somehow, we normalised products that look sleek on the outside and are deliberately inaccessible on the inside.

This isn’t progress.

It’s a design choice pretending to be modern.

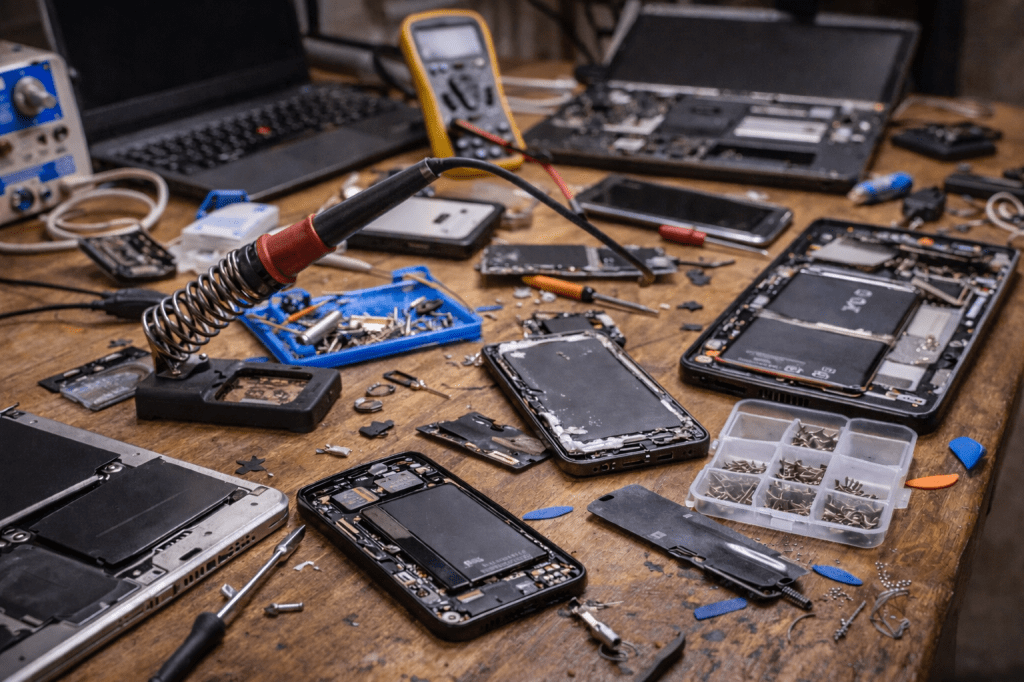

The Design Trend That Made Repair “Obsolete”

Over the last 15–20 years, manufacturers shifted from designing products to be opened to designing products to be sealed.

You can see it everywhere:

Phones with glued batteries.

Laptops with soldered RAM and storage.

Cars with software-locked components.

Appliances with sealed control boards.

Headphones that snap instead of unscrew.

Smart devices that stop working when one cheap sensor fails.

The internal logic changed.

Products stopped being machines.

They became sealed consumer objects.

Once that happened, repair stopped being a feature.

It became an inconvenience.

Why It Looks Good (But Works Badly)

Sealed, non-serviceable design photographs beautifully.

Thinner devices.

Smoother edges.

No visible screws.

No removable panels.

No seams.

On a product page, it looks premium.

In a showroom, it looks advanced.

On Instagram, it looks modern.

But in real life, it creates a different experience:

• higher repair costs

• longer downtime

• fewer independent repair options

• more landfill

• more forced upgrades

It’s a visual upgrade that creates a functional downgrade.

This is design for marketing, not for ownership.

How It Hurts Real Users

When serviceability disappears, small problems become expensive ones.

A £15 battery becomes a £250 “authorised repair.”

A £5 sensor becomes a £400 dealer visit.

A £10 power jack becomes a motherboard replacement.

A £2 capacitor becomes a full appliance write-off.

This changes behaviour:

People stop fixing.

They start replacing.

Not because repair is impossible.

Because it’s been made impractical.

That’s not innovation.

That’s forced obsolescence with better branding.

The Hidden Software Lock Problem

Modern products aren’t just physically sealed.

They’re digitally sealed.

Parts now need to be:

• paired

• coded

• registered

• activated

• authenticated

Even if you physically replace a component, the product may refuse to work until software approves it.

This is why:

• new car batteries need coding

• phone screens throw errors

• replaced cameras disable features

• appliances won’t recognise new boards

• third-party parts cause warnings

The hardware works.

The software blocks it.

Repair didn’t get harder because technology got complex.

It got harder because companies made it that way.

Why Manufacturers Do This

This isn’t about design ignorance.

It’s about control.

Sealed products create:

• controlled repair channels

• captive service revenue

• reduced third-party competition

• higher replacement rates

• shorter ownership cycles

Every sealed battery is a future upgrade.

Every coded part is a dealer visit.

Every glued panel is a barrier to DIY.

This is business logic, not design logic.

From a manufacturer’s perspective, a repairable product is a lost sale.

From a user’s perspective, a non-repairable product is a long-term cost.

Those incentives are no longer aligned.

What We Lost

Older products weren’t perfect.

But they were built with the assumption that things would be:

• opened

• cleaned

• adjusted

• replaced

• repaired

You could:

• swap a laptop battery

• change a phone back cover

• access car modules

• replace washing machine pumps

• change appliance belts

• fix power supplies

Ownership meant maintenance.

Now ownership means replacement.

That’s not modernisation.

That’s regression with better industrial design.

Why This Keeps Spreading

Once one major brand does it, everyone follows.

Not because it’s better.

Because it becomes “industry standard.”

Design teams copy competitors.

Cost teams love sealed assemblies.

Legal teams like controlled repair.

Marketing teams love clean aesthetics.

Nobody in the room is rewarded for making a product easier to fix in five years.

They’re rewarded for:

• thinner

• lighter

• sleeker

• cheaper to assemble

• harder to open

Serviceability loses every internal meeting.

What Smart Buyers Should Look For Instead

If you care about long-term ownership, avoid products that:

• glue critical components

• solder storage or memory

• require software pairing for parts

• hide screws under adhesive

• seal batteries inside frames

• block third-party parts

Look for products that still offer:

• removable panels

• standard fasteners

• modular components

• user-replaceable batteries

• documented parts

• independent repair support

These aren’t flashy selling points.

They’re ownership insurance.

The Blunt Truth

Modern design didn’t become anti-repair by accident.

It became anti-repair because it’s profitable.

It looks cleaner.

It sells upgrades.

It controls service.

It shortens product life.

And somehow, this became normal.

This isn’t innovation.

It’s inconvenience dressed up as progress.

Leave a comment