The Small Parts That Quietly Turn Into Big Repair Bills

Most breakdowns don’t happen because something “suddenly” failed.

They happen because a small, cheap part was quietly dying for months — and nobody noticed.

So one morning your car won’t start.

Your boiler stops heating.

Your washing machine floods the floor.

Your laptop overheats and shuts down.

And suddenly you’re not spending £10–£30.

You’re spending £300–£1,500.

Worse — the repair shop says:

“It’s not just the battery.”

“It’s not just the seal.”

“It’s damaged other parts too.”

That’s when a cheap replacement turns into a chain reaction.

Most people only replace things after they fail — when the damage is already done.

That’s why repair bills feel unfair.

It’s not bad luck.

It’s ignored wear items.

These are some of the most common parts that fail first — and they quietly cause the biggest repair bills.

Why This Keeps Happening

Most machines, vehicles, and home systems are built with sacrificial parts.

They’re designed to wear out first to protect bigger, more expensive components.

But nobody treats them like a checklist.

So people drive, wash, heat, and use — until the small part finally fails.

And when it does, it often takes something expensive with it.

This isn’t a design flaw.

It’s a preventive maintenance blind spot.

And it’s why people massively overpay for repairs that were completely avoidable.

How Small Problems Turn Into Big Bills

Here’s what usually happens:

• Small warning signs are ignored

• The part fully fails

• A repair service is called

• Multiple damaged parts are replaced

• Labour + emergency fees are added

• Days of use are lost

What could’ve been a £15 part becomes a £400 repair.

Not because it had to.

Because it was allowed to.

Replace These Before They Fail

These are some of the most common cheap parts that fail first — and cause expensive repairs when ignored.

Car Battery (Every 3–5 Years)

Batteries degrade quietly. Cold weather finishes them off.

If you don’t replace it early, you get no start, a call-out fee, missed work, and possible alternator strain.

If your battery is over 3 years old, replacing it before winter is cheaper than one breakdown.

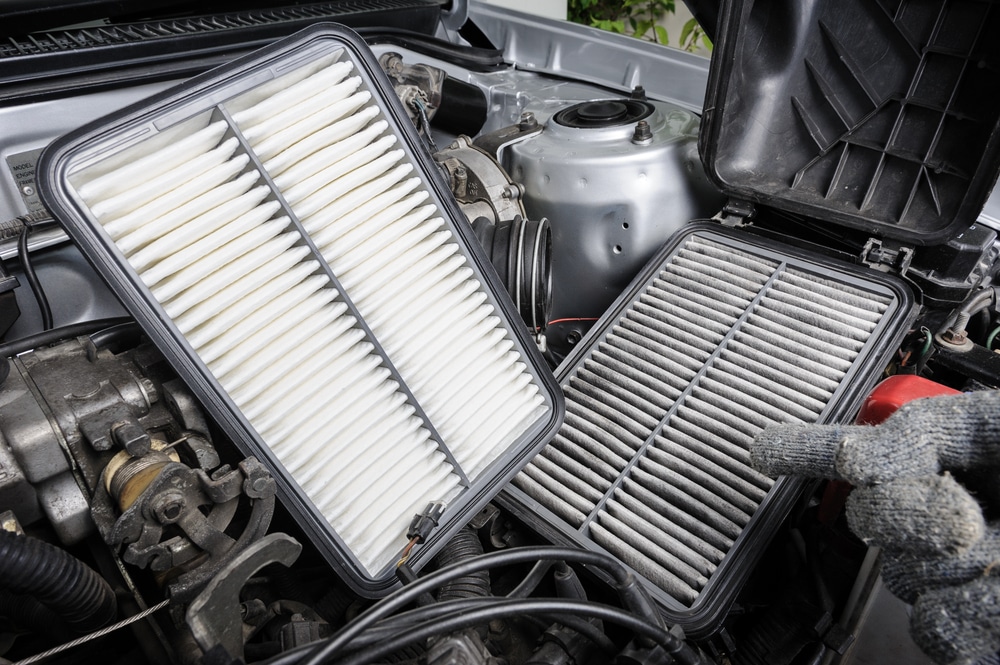

Engine Air Filter (Every 12 Months)

Air filters clog slowly and starve the engine of air.

That hurts MPG, causes rough running, and increases engine wear.

A £10–£20 filter is a 2-minute DIY job that protects the engine.

Washing Machine Hoses (Every 5–7 Years)

Rubber hoses degrade and eventually split under pressure.

When they fail, you get a flooded kitchen, water damage, and an insurance excess.

Replacing hoses preventatively is one of the cheapest ways to prevent major home damage.

Boiler / Heating System Pressure Relief Valve

Mineral buildup and heat cycling wear these out.

When they fail, you get pressure loss, lockouts, and emergency call-outs.

Replacing it during routine servicing is far cheaper than a breakdown visit.

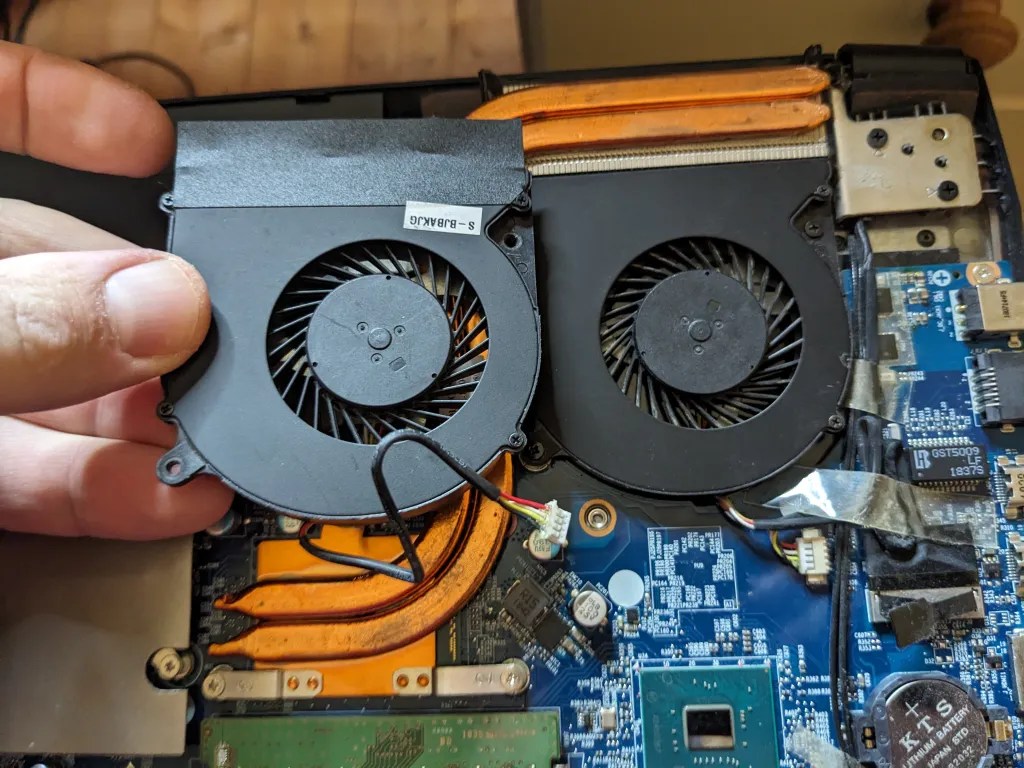

Laptop Cooling Fan

Dust and bearing wear cause fans to fail quietly.

When they go, laptops overheat, throttle, and risk motherboard damage.

Replacing noisy fans early and cleaning vents regularly prevents heat-related failure.

Fridge Door Seals

Door seals harden and small gaps form.

That makes the compressor work harder, increases electric bills, and shortens fridge life.

A new seal is cheap. A new fridge is not.

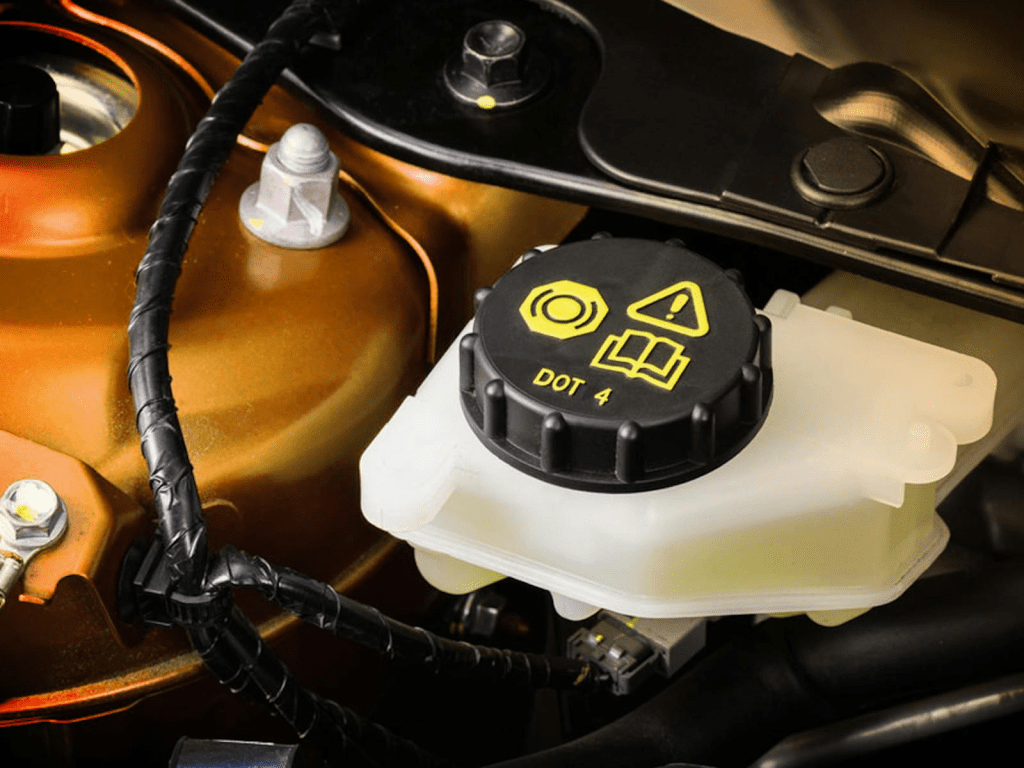

Car Brake Fluid (Every 2–3 Years)

Brake fluid absorbs moisture over time.

That causes corrosion, soft pedal feel, and potential ABS issues.

Fluid changes are cheap. Brake system repairs are not.

Simple Tools That Prevent Expensive Repairs

These basic tools can pay for themselves the first time they prevent a breakdown:

• Battery tester — spot a dying battery early

• OBD scanner — catch hidden car faults

• Infrared thermometer — find overheating components

• Lint and dust cleaning kits — prevent appliance and laptop overheating

• Replacement hose and seal kits — cheap insurance against floods

• Multimeter — quick electrical checks

A £15–£40 tool can stop a £300–£1,000 repair.

That’s why people who own these almost always save money long-term — even if they don’t realise it.

The One Part Most People Replace Too Late

Serpentine belts and drive belts.

They often look fine right up until they snap.

When they go, you can lose power steering, charging, cooling, and accessories in one hit.

Belts are cheap.

Breakdowns caused by snapped belts are not.

If you don’t know when yours was last changed, it’s already overdue.

The Mistakes That Make This So Expensive

• Waiting for total failure

• Ignoring small noises or smells

• Resetting warning lights instead of fixing causes

• Skipping basic servicing

• Replacing only after collateral damage

• Assuming “it’s probably fine”

That’s how £20 problems become £500 repairs.

How Often You Should Check These

Use this simple preventive maintenance checklist:

• Car wear items: Every service

• Appliances: Once a year

• Heating system: Every annual service

• Electronics: Every 6–12 months

• Hoses, seals, rubber parts: Every 5 years minimum

Put it in your calendar.

Five minutes of checking beats hours of breakdowns.

When You Should Not DIY

Don’t DIY if:

• Gas systems are involved

• Electrical panels are involved

• You see corrosion on structural components

• The fix affects braking or steering

• You’re unsure about pressure systems

Preventive replacement is smart.

Dangerous guessing is not.

Final Takeaway

Most expensive failures start as cheap, ignored parts.

That’s why people feel ripped off by repairs — when the truth is they missed the cheapest window to fix it.

Replace the small stuff early.

Avoid the big stuff later.

Five minutes now saves hundreds later.

Most people ignore this — that’s why they overpay.

Leave a comment